Quality Control of LCD Screen

Are you concerned about the LCD display’s quality before making the final payment?

Would you like to learn about the comprehensive process and specific details of LCD display quality control?

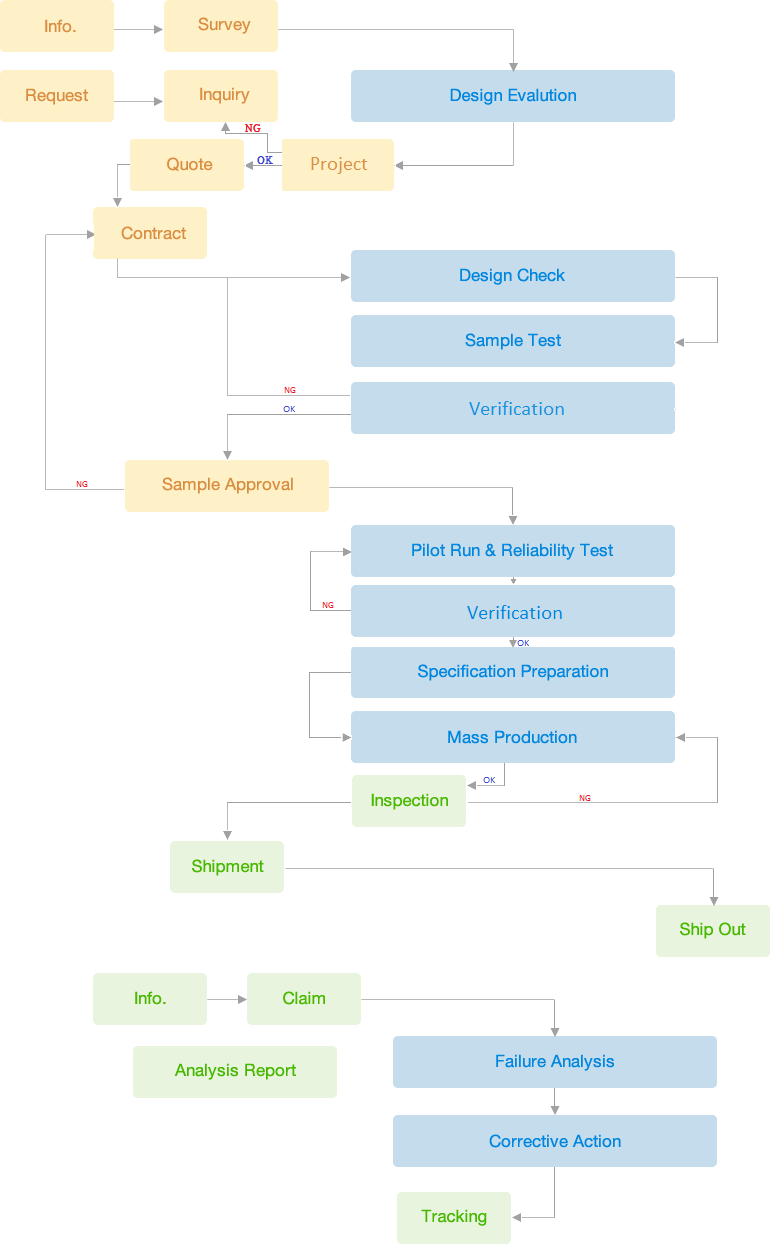

Beten, as a professional LCD display manufacturer, follows a thorough and stringent quality control process.

Beten implements strict quality inspections at each stage of LCD display production.

Beten offers visual evidence through pictures and videos of the LCD display quality inspection, along with a checklist for quality inspection.

Quality Control Standards

Beten products have obtained international quality and safety certifications administered by reputable organizations. Our commitment to quality sets the foundation for excellence in all aspects of our manufacturing process. Certifications include:

- ISO 9001 Certificate

- ISO 14001 Certificate

- IPC Qualified Manufacturers

- Total Quality Management

- Periodical Reliability Test

Quality Inspection Videos

At Beten, we place great importance on quality. For every order, we conduct rigorous inspections at each step to ensure consistent and stable quality. Our commitment to delivering superior quality ensures the complete satisfaction of our customers, fostering long-term partnerships.

Quality Control & Assurance

Quality materials are the foundation of excellence. At Beten, we consistently conduct rigorous quality inspections of raw materials prior to production. Our quality control measures include:

- AQL Standard Sampling Inspection

- Incoming Engineering, Mechanical, Electronic & Optical Testing

- Vendor Quality Auditing

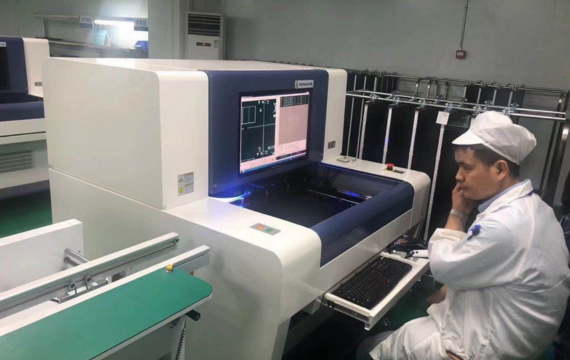

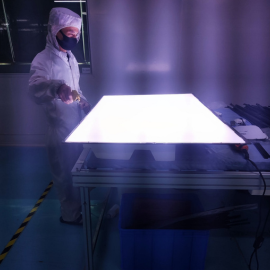

Throughout the production process of LCD displays, Beten maintains strict control over each production step and maintains a clean production workshop environment. At the completion of each production step, we conduct thorough quality inspections to ensure there are no issues before proceeding to the next step. Our quality control measures include:

- Online QC (Cleaning, Printing, Chip Position)

- 100% Best & Inspection after Wire Bonding (Electronic, Optical)

- Final Testing & Inspection (100% QC, Mechanical, Electronic, Optical)

- IPC QML (Classes 1 and 2)

- Functional Testing of LSI, LCD, Contrast, etc.

After completing the production process, we perform a series of tests to ensure that our screens meet international quality standards for LCD displays. Additionally, we provide customers with quality inspection pictures, videos, and reports before shipping. Our testing procedures include:

- Functional Testing (Electronic, AC/DC, Pin Terminal, Mechanical)

- LCM QC Testing (Contrast, Characters, Display, etc.)

- Sampling QC according to AQL Standard (Value=0.65)

Reliability Conditions

- Reliability Conditions

- Quality Control and Assurance Standards

- High-Temperature Aging Test

Once the LCD display assembly production is complete, our engineers subject it to a 72-hour high-temperature aging test in a dedicated testing lab. This test aims to simulate the operating environment of the LCD display and identify any potential faults before the product reaches your hands. - High and Lower-Temperature Thermal Shock

Prior to delivery, your LCD displays undergo rigorous high-low temperature thermal shock experiments. This ensures that the devices can function normally under varying temperature conditions. - Random Vibration Test

This test simulates vibrations and assesses the device’s ability to withstand shocks or bumps during transportation. It guarantees that you receive flawless devices even after long-distance shipping. - Salty Spray Test

The purpose of this test is to evaluate the anti-corrosion properties of the surface treatment and the adhesion of the coating. The salty spray test enhances the longevity of interactive flat panels and enhances the reliability and durability of the device.